Custom Forged Wheels Manufacturer for B2B | Wholesale with MOQ 1 Set

Factory-direct forged wheels with precision machining, reliable delivery, and fully compliant invoices – perfect for dealers, tuners, EV makers, and online wheel stores.

• MOQ starts from just **1 set** – ideal for testing and custom orders

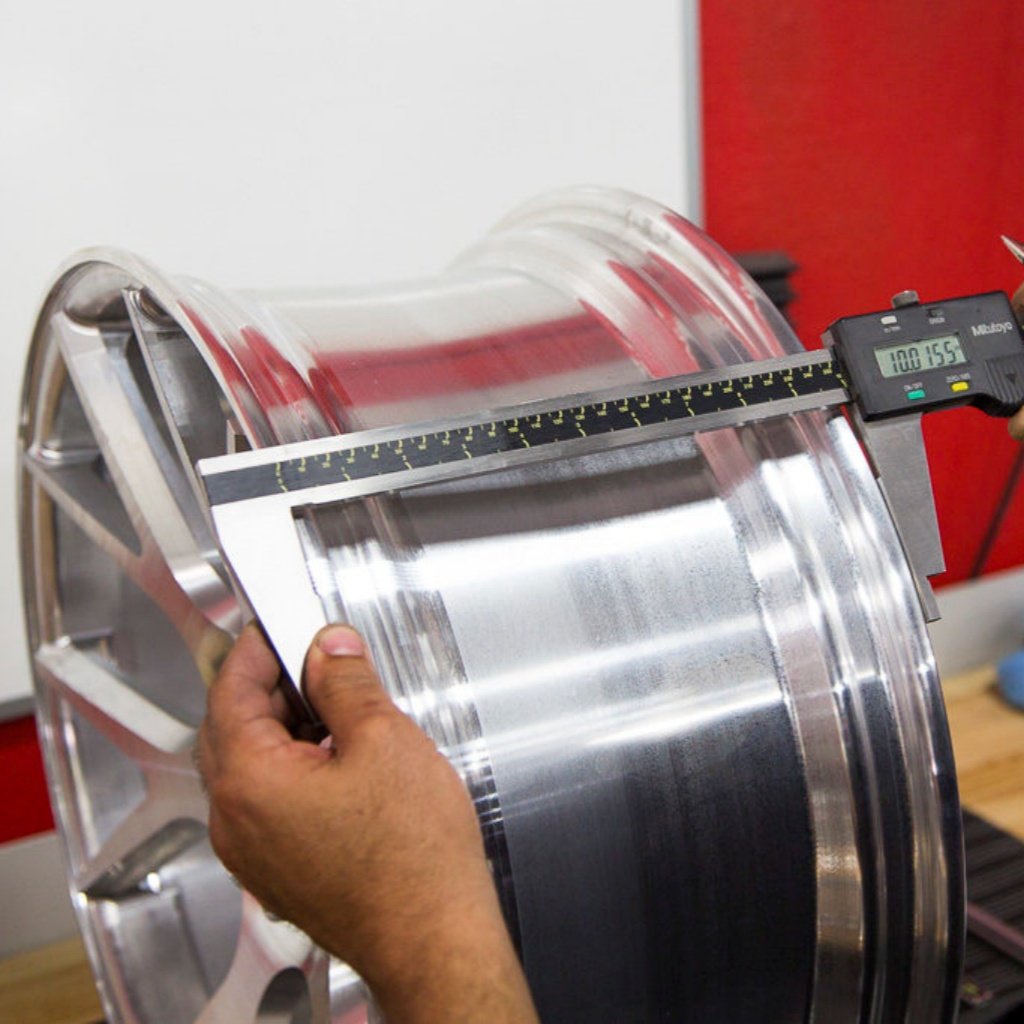

• CNC machined: 3/4/5-axis with runout ≤ 0.01″

• Full range: 12–34″ | monoblock, 2-piece, 3-piece, beadlock

• Private label: custom finishes, center caps & engraving

• Stable lead times | 100% accurate invoice & customs support

Build Your Wheels in 3 Steps — Easy & Reliable

From billet to finish, we control machining and finishing in-house for consistent quality. You get clear drawings, firm timelines, and compliant paperwork—every time.

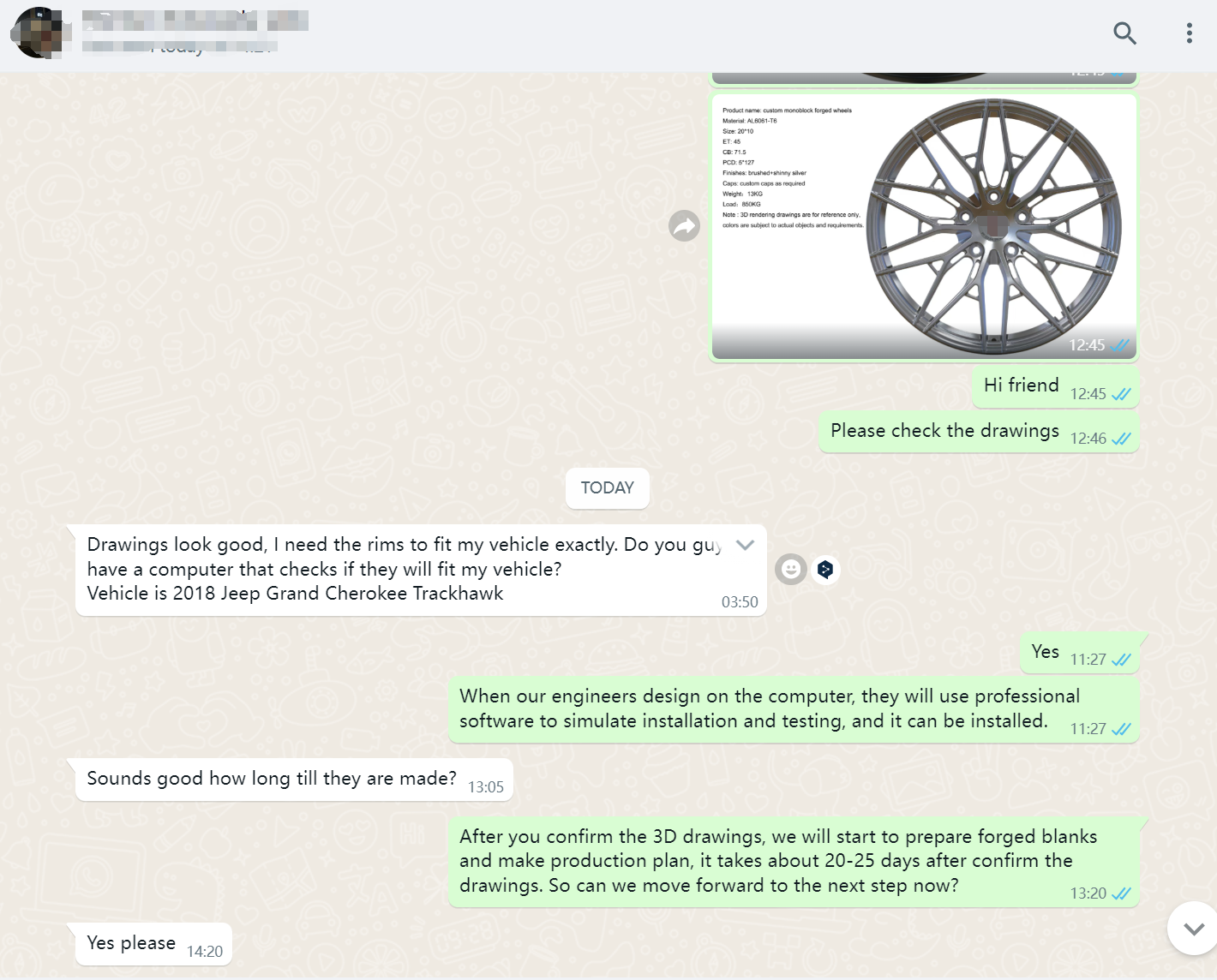

Spec & Drawing — size/PCD/ET/CB confirmed with 2D/3D approval

Manufacture — forging, CNC, finishing, 100% QC with runout test

Ship & Support — EXW/FOB/CIF, tracking & after-sales within 24h

Forged Wheels for Every Build — From Monoblock to Beadlock

Monoblock for lightweight performance. 2-piece/3-piece for fitment freedom. Beadlock for off-road grip. Carbon+forged & motorcycle options available.

- Precision Engineered for Performance

- Fully Customizable Solutions

- Rigorous Quality Control

- Sustainable Manufacturing

- Global Reach, Local Service

- Blank Wheels Available If needed

Services for B2B Buyers

Manufacturing:T6-6061, 3/4/5-axis CNC, sizes 12–34″, ±0.05 mm tolerance

Customization:Monoblock/2-Piece/3-Piece/Beadlock, caps & logos, private label

Quality & Papers:100% runout check, material certs on request, invoices with tax/VAT details

Logistics:EXW/FOB/CIF, EU/US-ready packing, HS code & documents prepared

Customization Options

At FLEXIFORGED Wheels LLC, we specialize in delivering custom solutions to meet the unique needs of our clients. Our bespoke services cover three main areas of customization: size, shape/structure, and finishes.

Size Customization

- Size-diameter

- Size-width

- PCD-bolt pattern

- CD-center bore

- ET-offset

Shape Customization

- Forged Wheels

- Forged Off-Road Wheels

- Carbon+Forged Wheels

- Forged Motorcycle Wheels

- Forged Magnesium Wheels

Finishes Customization

- Painting

- Polishing

- Brushed

- Anodizing

- Chrome

Our 8-Step Manufacturing Process

From engineered CAD to finished wheels, FLEXIFORGED runs a controlled, traceable workflow that keeps your specs tight, lead times predictable, and paperwork compliant. Every wheel is inspected before shipping to ensure fitment, strength, and a premium finish.

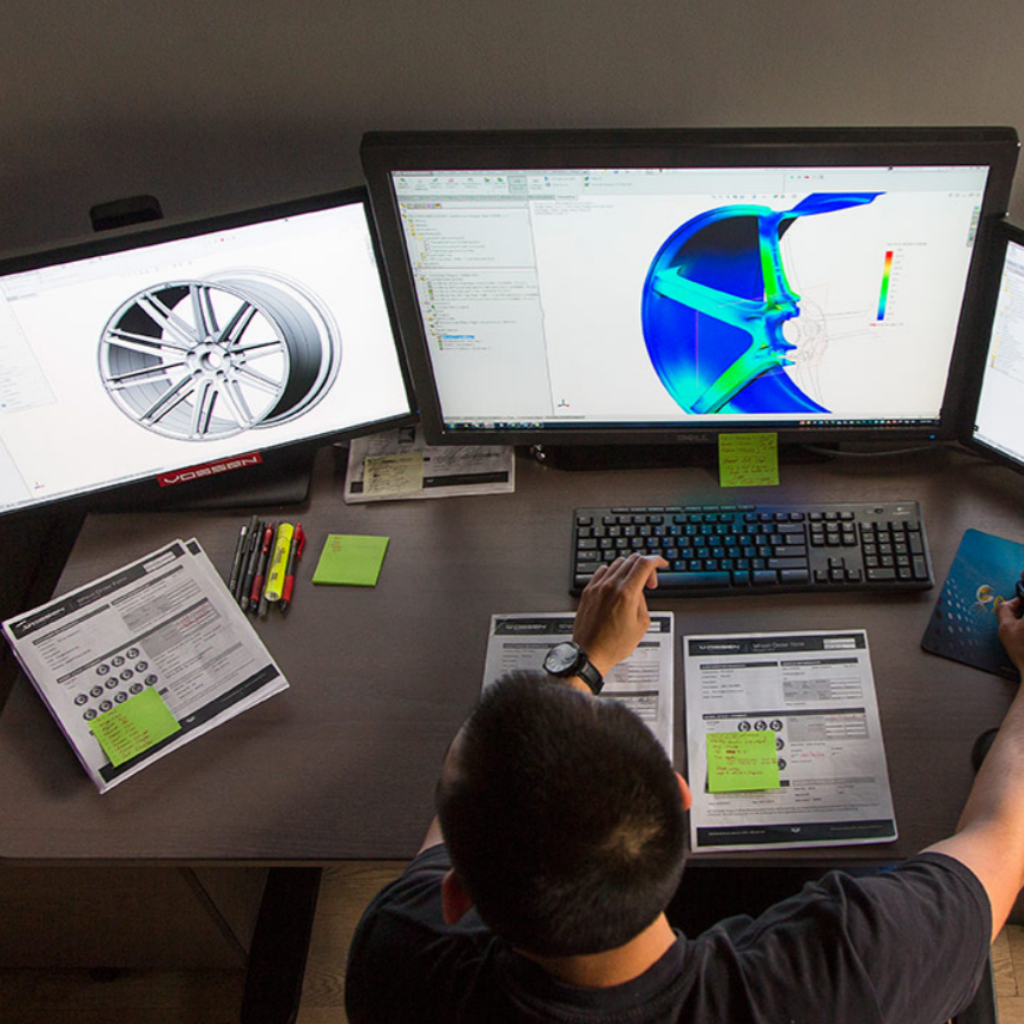

Step 1 — Programming (CAD → CAM)

We convert your approved CAD into CAM toolpaths and simulate cutting to avoid collisions and chatter. G-code, tools, and fixtures are documented under revision control for repeatable accuracy and faster reorders.

Step 2 — Initial Lathe Turning

The raw forging is profiled inside and outside to establish geometry and concentricity, removing over 70% of excess material. This sets a precise foundation for milling and finishing.

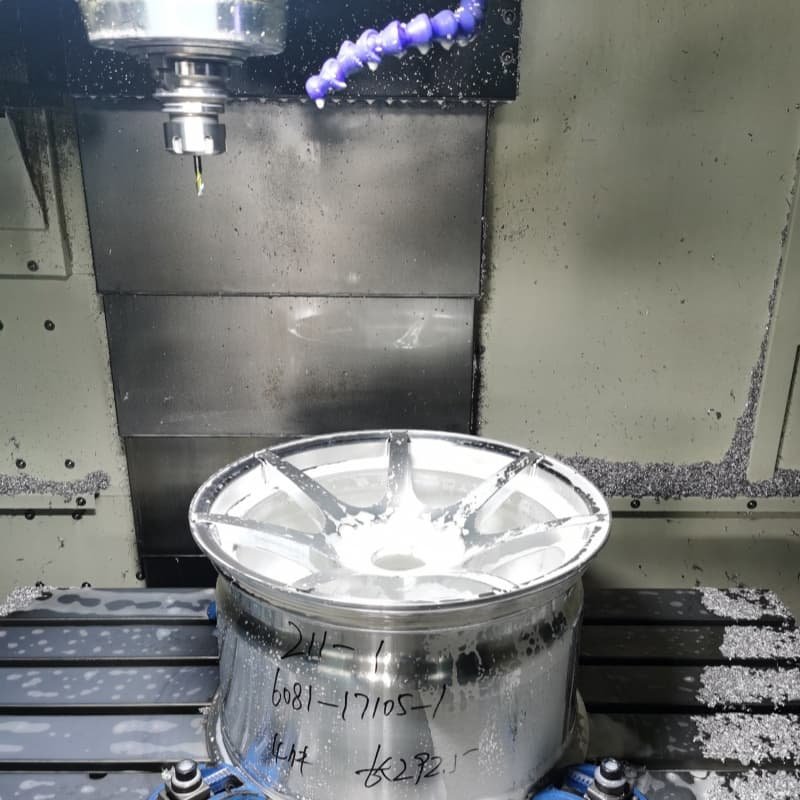

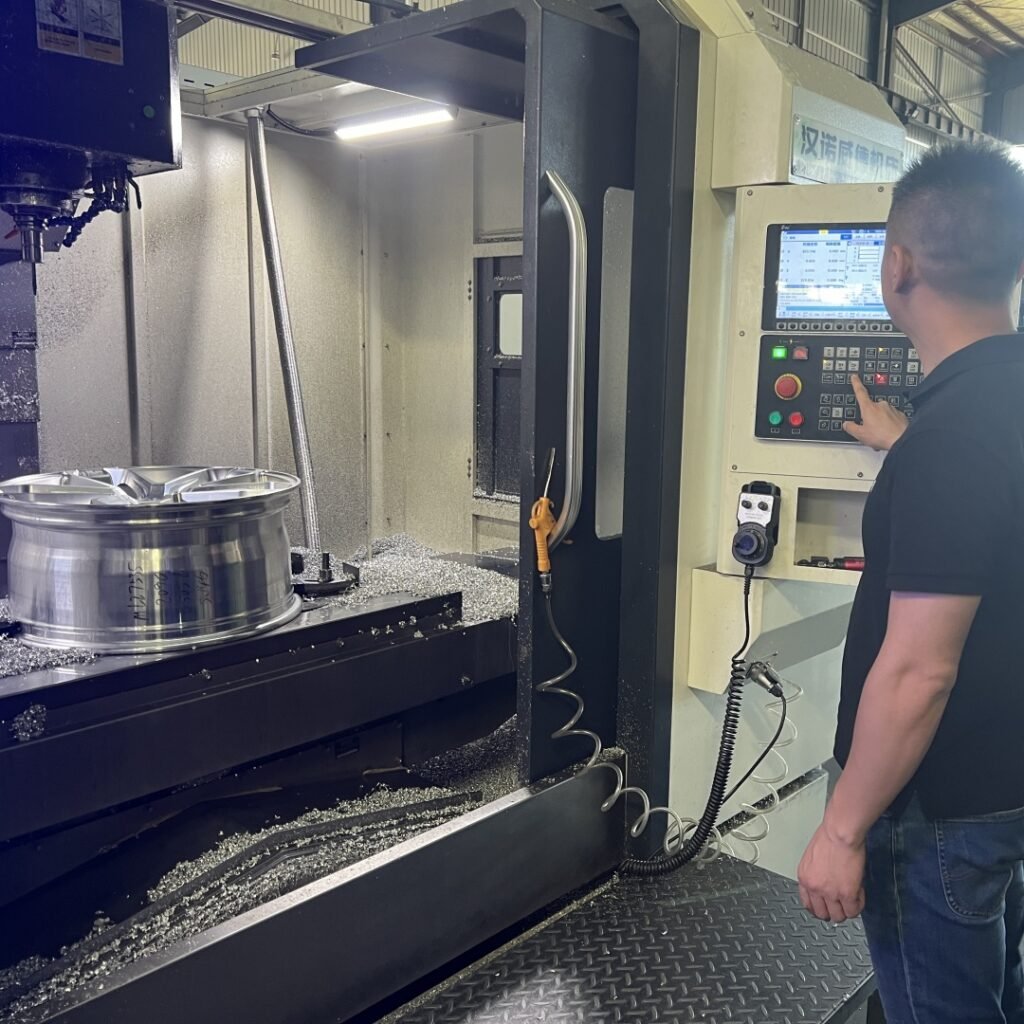

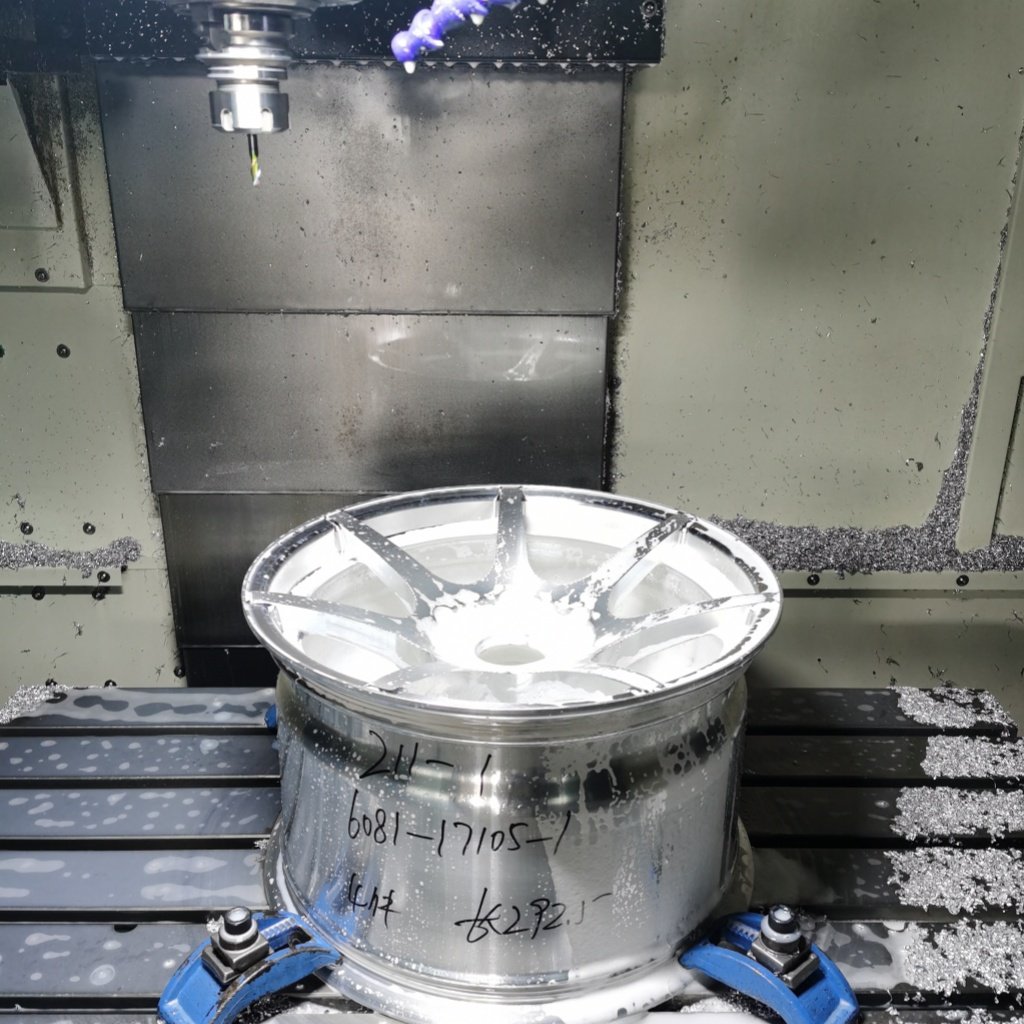

Step 3 — CNC Milling

3/4/5-axis CNC brings out the spoke design and window details. Typical passes remove as little as 0.02″ per cut to protect surface integrity, improve balance, and hit your design intent.

Step 4 — Lightening

We machine engineered lightening pockets on the back pad to reduce rotating mass while maintaining strength at critical load paths. The result is quicker acceleration and more responsive handling.

Step 5 — Engraving

Each wheel is laser/CNC-engraved with serial number, size, offset, center bore and load rating for full traceability. Private-label logos and cap branding are available on request.

Step 6 — Final Lathe Turning

The wheel is re-set and centered within 0.001″ of the spindle axis. Final trims true the profile to achieve runout < 0.01″ and uniform chamfers—ready for coating or polishing.

STEP 7-Quality Control

Every wheel undergoes 100% runout testing, dimensional checks, and cosmetic inspection. Only parts meeting spec move to packing; QC records and media can be shared on request.

Step 8 — Finishing

We apply powder coat, brushed/polished treatments, anodizing or chrome to meet your aesthetic and corrosion-resistance targets. Chrome/anodize are performed by audited partners; final inspection is done by FLEXIFORGED before shipment.

Trusted by Customers Worldwide

At FLEXIFORGED, we don’t just make forged wheels — we build lasting partnerships.

From performance tuning shops to OEM suppliers around the world, our clients trust us for precision, reliability, and results.

See how businesses like yours work with us to deliver outstanding wheel customization projects.

Forged Wheels FAQ for B2B Buyers

Small MOQ is available. Standard starts from 4 pcs per spec; mixed sizes in one order are acceptable.

Samples 10–15 working days; mass production 20–30 working days, add +5 days for complex finishes or peak seasons.

Diameter × width, PCD, center bore (CB), offset (ET), quantity per spec, finish, trade term (EXW/FOB/CIF), destination port, and invoice details (company name, address, VAT/tax No.).

Yes—commercial invoice with invoice number, company/VAT details, packing list, and HS code 8708.70 (road wheels & parts). Certificates/material reports are available on request.

100% runout test, typical tolerance < 0.01″; key dimensions ±0.05 mm; each wheel has a serial number and QC record (photos/videos on request).

Yes—center caps, engraving, packaging with your brand. NDA is available.

Built to application. Passenger/performance wheels typically 690–955 kg; off-road applications higher. Ratings are shown on drawings and engraved.

Powder coat, brushed, polished, anodized or chrome. Chrome/anodize via audited partners; final inspection by FLEXIFORGED.

We issue a 2D/3D approval drawing; machining starts after you approve. If delivered wheels deviate from the approved spec, we rework or replace.

EXW/FOB/CIF; sea/air available. Foam + bag + carton + corner protectors; palletized for bulk. Pre-shipment photos provided.

T/T 50% deposit, 50% before shipment. USD/EUR/CNY accepted. Alibaba Trade Assurance can be arranged for some orders.

12-month warranty for manufacturing defects. Finish wear from chemicals/abrasives or impact damage is excluded. Response within 24h for any after-sales case.

Get a Quote or Download E-Catalog

Send your specs or drawing. We confirm details and quote EXW/FOB with MOQ and lead time within 24 hours.