If you’ve spent time around custom car shops, bike builders, or performance forums, you’ve probably heard people talk about “billet rims.” The term sounds premium—and it is—but what exactly does “billet” mean? Are billet wheels really stronger? And how do they compare to cast or forged wheels?

This guide breaks everything down in a clean, practical way, using real industry knowledge from the world of custom forged wheels. Whether you’re building a show truck, tuning a sportbike, or sourcing small-batch wheels for your business, this article will help you understand billet rims like a pro.

What Exactly Are Billet Rims?

In simple terms, a billet rim is made from a solid block of high-grade aluminum (called a billet) that is carved into shape using CNC machining.

Unlike cast wheels, which are poured into a mold, billet wheels are cut, shaped, and sculpted from a single chunk of metal.

Because of this, billet rims are known for:

- Extremely high machining precision

- Perfect symmetry

- Custom shapes that molds can’t produce

- Premium finish quality

Most billet wheels are made from 6061-T6 aluminum, the same material used in aerospace, performance parts, and forged wheels.

How Billet Wheels Are Made

Billet wheels are all about precision. A typical manufacturing process looks like this:

1. Selection of the Billet Block

A solid cylindrical block of 6061-T6 or sometimes 7075 aluminum is chosen depending on strength or weight goals.

2. CNC Machining

This is the heart of the process—5-axis or 7-axis CNC machines carve the wheel shape layer by layer.

This method allows:

- incredibly sharp design lines

- deep cuts

- unique patterns

- repeatable accuracy

Every spoke, lip, and detail is controlled down to fractions of a millimeter.

3. Finishing

After machining, the wheel undergoes finishing, such as:

- brushing

- polishing

- anodizing

- powder coating

- two-tone or contrast cuts

The finish quality of a billet wheel is often unmatched because the entire wheel starts as a clean, solid block.

Billet vs Forged Wheels: What’s the Difference?

This is the most common question people ask.

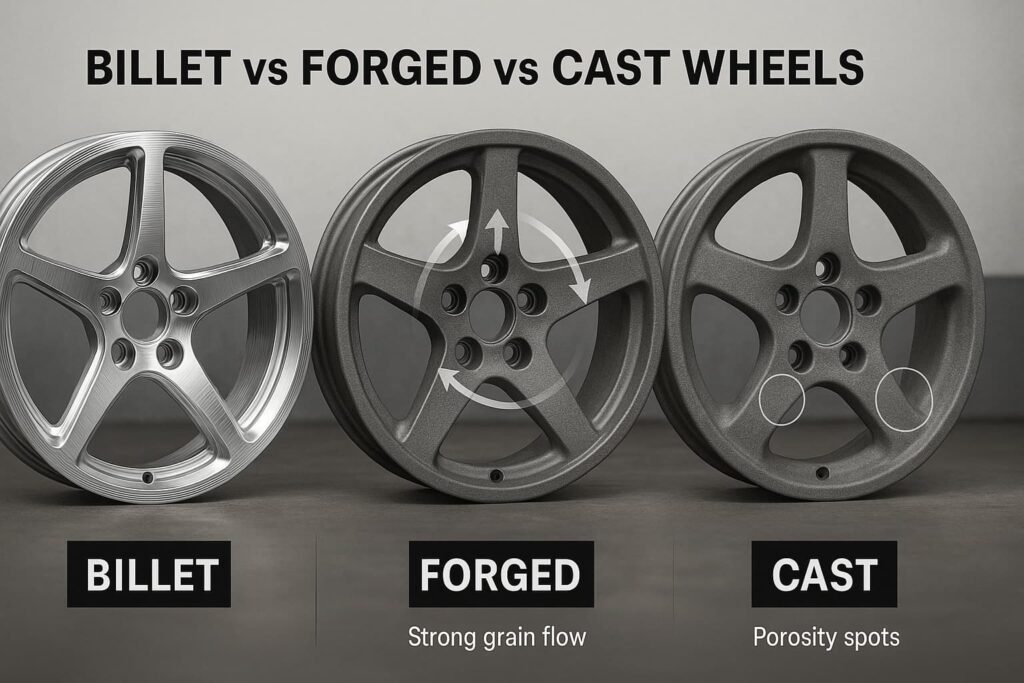

Although billet and forged wheels are often mentioned together, they’re not the same.

Billet Wheels

- Machined from a solid block

- Amazing precision

- Best for custom one-off or low-volume production

- Very clean surface finish

- Strong, but grain structure is not directional

Forged Wheels

- Aluminum is pressed under massive pressure before machining

- Grain flow follows the wheel’s shape

- This gives higher strength and better fatigue resistance

- Ideal for hard driving, racing, or heavy loads

So Which Is Stronger?

For pure strength, forged wheels win because of grain flow alignment.

But CNC billet rims shine in:

- design flexibility

- machining accuracy

- custom low-volume or show builds

- lightweight motorcycle wheels

- unique spoke geometry

Many premium manufacturers (including us at FLEXIFORGED/FLEXIMOTO) combine both:

forged billet wheels, which means the wheel is forged first, then CNC-machined for final shape.

This delivers the best of both worlds.

Why People Choose Billet Wheels

Billet wheels have a very loyal following—and for good reason.

1. Unmatched Precision

CNC billet machining delivers tolerances far tighter than cast manufacturing. Every edge is perfect.

2. Incredible Customization

You can change:

- spoke design

- lip depth

- weight pockets

- engraving

- finishing

- fitment

Any detail you can draw, a CNC machine can cut.

3. Great for Small Batch Production

Ideal for:

- custom car shops

- motorcycle builders

- concept vehicles

- restorations

- one-off designs

No expensive mold needed.

4. Premium Look

A billet wheel has a “cut from metal” aesthetic that cast wheels can’t imitate.

Are Billet Rims Strong Enough for Daily Use?

Yes—billet rims are strong, especially when made from aerospace-grade 6061-T6.

However, strength depends on:

- type of billet

- machining design

- how thin the spokes are cut

- load requirements

- whether the wheel is forged before machining

For aggressive driving, racing, or heavy vehicles, forged billet is recommended.

For motorcycles, hot rods, custom trucks, and show builds, billet wheels perform extremely well and look incredible.

Best Vehicles for Billet Wheels

Because of their design flexibility and premium finish, billet rims are especially popular with:

Cars & Trucks

- Muscle cars

- Hot rods

- Classic restorations

- SEMA-style show builds

- Lifted trucks

- Dually trucks (polished billet is a trend)

Motorcycles

- Sportbikes

- Scooters

- Custom café racers

- High-end cruisers

- Lightweight performance builds

FLEXIMOTO customers often choose billet rims for motorcycle front wheels, where weight and precision matter the most.

Custom Billet Wheels (FLEXIFORGED / FLEXIMOTO)

At FlexiForged, we specialize in small-batch billet and forged billet wheels for both cars and motorcycles.

Whether you need one set or a full production run, we can support:

- monoblock billet wheels

- 2-piece / 3-piece billet wheels

- forged billet wheels

- motorsport-spec machining

- JWL/VIA–based structural design options

- custom fitment for any vehicle

We can work from your design, CAD file, or even a sketch.

If you’re looking for custom billet wheels, just send us your vehicle model or wheel idea — we’ll take care of the rest.

Frequently Asked Questions (FAQ)

1. Are billet wheels stronger than cast wheels?

Yes. Cast aluminum has random grain and more porosity. Billet aluminum is denser and machined with higher precision.

2. Are billet wheels stronger than forged wheels?

Forged wheels are still stronger due to directional grain flow, but billet wheels offer better design freedom.

3. Are billet motorcycle wheels lighter?

Yes. CNC machining can remove excess material, often resulting in very lightweight designs.

4. Do billet rims crack easily?

High-quality billet wheels rarely crack unless the design is poorly engineered or cut too thin.

5. Are billet wheels expensive?

Yes—billet rims are premium because they require hours of CNC machining and use solid aerospace-grade aluminum.

6. Can billet wheels be customized?

Absolutely. Spokes, lip styles, engraving, finish colors, offset, and PCD can all be tailored.

Conclusion

Billet rims sit at the intersection of precision engineering, craftsmanship, and custom automotive culture. Whether you’re building a one-off motorcycle project or developing a new wheel line for your company, billet wheels offer unmatched detail, accuracy, and flexibility.

If you’re exploring custom billet or forged billet wheels, we’d love to help.

From design support to low-volume production, FLEXIFORGED is here to bring your ideas to life.