Custom Wheel Spacers Supplier in China

Delivering High-Quality, Tailored Solutions for Your Business Needs

Precision Custom Wheel Spacers Supplier - The Ultimate Solutions

Looking to source precision custom wheel spacers? This comprehensive guide will provide everything you need to know about custom design and production services for wheel spacers.

Hi, I'm Jackie from FLEXIFORGED. Let me guide you through this ultimate solutions page.

Table of Contents

Download this page as a PDF

To save you time, we have also prepared a PDF version containing all the contents of this page, only leave your email and you will get the download link immediately.

Why Choose FLEXIFORGED ?

We are a company dedicated to customer satisfaction, aiming to produce and deliver high-quality custom wheel spacers to meet all your needs.

With over 10 years of experience in the auto parts industry, FLEXIFORGED is well-versed in this field. You are dealing with experts who understand your expectations and requirements.

Need proof? Contact us to schedule a virtual inspection session. We ensure that you can verify the quality of our products conveniently and efficiently.

Each wheel spacer is precision-engineered from top-grade materials, making them durable, reliable, and perfectly suited for various automotive applications. This translates into improved performance, safety, and longevity.

With FLEXI, you’re not just buying a product; you’re configuring it. From size and finish to intricate design details, our wheel spacers are customizable to align perfectly with your and your clients’ specific needs.

Leveraging decades of experience and state-of-the-art technology, we ensure that every wheel spacer is a testament to our commitment to excellence.

We navigate the complexities of international standards and shipping logistics to deliver our top-quality wheel spacers wherever you are—effectively and efficiently.

Want to know how we can help your business succeed? Let’s talk!

Hot Products Based on Client Feedback

At FLEXI, we specialize in producing high-quality wheel spacers and adaptors tailored to diverse automotive needs. Here are some of our top products that customers frequently commend:

Bolt-On Spacers Designed for easy installation, our bolt-on spacers provide a secure fit and are perfect for clients looking to enhance vehicle stability and wheel fitment.

Slip-On Spacers Ideal for quick adjustments, these spacers slip over the existing hub, allowing for minor clearance alterations without extensive modifications.

Thread Insert Adaptors These adaptors provide a reliable solution for fitting wheels with different bolt patterns, ensuring compatibility across various makes and models.

Hub-Centric Spacers Tailored to match precisely with the wheel hub, these spacers ensure a perfect alignment and balance, improving both safety and driving dynamics.

Estimated Cost Analysis for Custom Wheel Spacers

When considering custom wheel spacers for your automotive needs, it is crucial to understand the various factors that contribute to the final cost. Below is a detailed breakdown of the cost components to help you make informed decisions.

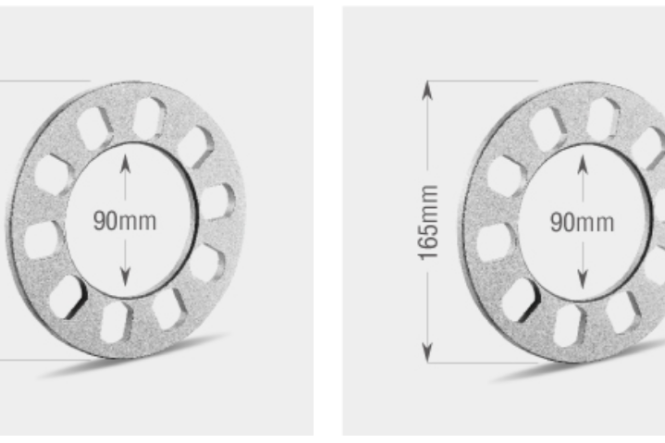

1. Size Specifications

The dimensions of the wheel spacers, such as diameter, thickness, and overall shape, directly influence the material usage and machining time. Larger and more complex spacers require more material and sophisticated machining processes, akin to how a larger blueprint in construction demands more resources.

2. Material Selection

The choice of materials significantly affects the cost. Common options include high-strength aluminum alloys like 6061-T6 or 7075-T6. Aluminum alloys are preferred for their balance of strength, weight, and cost-effectiveness. However, opting for higher-grade materials will increase the cost, similar to choosing a high-performance engine for a vehicle.

3. Manufacturing Process

Raw Material Preparation

- Selection: Choosing suitable aluminum or steel bars, typically high-strength aluminum alloys such as 6061-T6 or 7075-T6.

- Cutting: Cutting the bars into appropriate lengths for further processing.

Forging Blanks

- Heating: Heating the cut material to an appropriate temperature for optimal plasticity.

- Forging: Using forging equipment like hammers or hydraulic presses to create the initial spacer blank, which enhances material density and strength.

- Cooling: Controlled cooling to maintain material stability.

- Trimming: Removing excess material to achieve the desired rough dimensions.

Machining

- Turning: Using CNC lathes to perform preliminary turning, shaping the basic outline of the spacer.

- Drilling: Drilling bolt holes and center holes, including machining center rings if needed.

- Milling: Further milling to add grooves and details as per design requirements.

- Chamfering: Chamfering edges to avoid sharp edges and ensure safety.

Heat Treatment (if needed)

- Heat Treatment: Enhancing the strength and durability of high-performance spacers through heat treatment processes.

4. Surface Finishing

Different surface finishes add aesthetic appeal and corrosion resistance but also increase the cost. Options include:

- Polishing: Improving surface smoothness and shine.

- Anodizing: Adding a protective oxide layer to aluminum spacers, available in various colors for enhanced appearance and corrosion resistance.

- Painting or Plating: Applying coatings to steel spacers to prevent rust and improve visual appeal.

5. Quality Assurance and Testing

Ensuring the wheel spacers meet high-quality standards involves various tests:

- Dimensional Inspection: Using calipers and micrometers to verify dimensions.

- Concentricity Inspection: Checking the alignment of center and bolt holes for balance.

- Hardness Testing: Confirming material strength post-heat treatment.

- Surface Quality Inspection: Ensuring uniform and defect-free surface finishes.

6. Packaging and Logistics

- Assembly (if needed): Assembling complex spacers with additional components like center rings.

- Cleaning: Removing any residual machining oils and impurities.

- Packaging: Using protective materials to safeguard spacers during transportation, with clear product information and batch numbers for traceability.

7. Transportation Distance and Mode

The shipping distance and method (air, express, rail, sea) play a significant role in the final cost. Longer distances and faster shipping methods like air freight are more expensive, similar to how overnight shipping in e-commerce costs more than standard delivery.

8. Local Policies and Import Taxes

Local regulations, import taxes, and fees vary by region and can significantly impact the final cost of imported wheel spacers. These are akin to international trade where tariffs and regulations dictate market accessibility and pricing.

Estimated Manufacturing and Shipping Times

We work fast. With the increasing number of customers approaching us, we prioritize speed. Here’s a look at the entire process of manufacturing and shipping wheel spacers:

STEP 1

Design and Manufacturing Time

We start by designing and manufacturing the wheel spacers. This includes refining raw materials, forging, and machining to ensure high precision and quality.

STEP 3

Custom Clearance and Loading Time

The packed products are loaded onto vehicles. After clearing customs, the products are transported to various dispatch points.

STEP 2

Packing and Boxing Time

Our staff carefully packs the wheel spacers in protective cartons. This step is quick and ensures that all products are secure for transportation.

STEP 4

Sea and Land Transportation Time

Once the products arrive at their destination, you will receive an alert. You can then plan how to collect your shipped goods.

The Whole Process of Custom Wheel Spacers

This is what we do when it comes to making custom wheel spacers:

1

Initial Design and Concept

We start by consulting with our clients to understand their specific needs and preferences. Our design team creates detailed blueprints and 3D models to ensure the spacers meet all functional and aesthetic requirements.

2

Raw Material Preparation

- Selection: We select high-strength aluminum alloys such as 6061-T6 or 7075-T6, ensuring the material’s strength and durability.

- Cutting: The selected bars are cut into appropriate lengths, ready for subsequent processing.

3

Forging the Blanks

- Heating: The cut material blocks are heated to an appropriate temperature to achieve good plasticity.

- Forging: Using forging equipment (like forging hammers or hydraulic presses), the heated material is forged into the initial spacer blank. This process increases the material’s density and strength.

- Cooling: The forged blanks are slowly cooled to maintain the stability of the internal structure.

- Trimming: Excess material is trimmed to achieve the desired rough dimensions.

4

Precision Machining

- Turning: The forged blanks are placed on CNC lathes for preliminary turning, forming the basic shape of the spacer.

- Drilling: Bolt holes and center holes are drilled into the spacers. For spacers with center rings, the center ring part is also machined.

- Milling: According to design requirements, further milling is done to add necessary grooves and details.

- Chamfering: The edges of the spacers are chamfered to avoid sharp edges and ensure safety.

5

Surface Finishing

- Polishing: The machined spacers are polished to improve surface smoothness and shine.

- Anodizing: Aluminum spacers are anodized, adding corrosion resistance and enhancing appearance with various color options.

- Painting or Plating: Steel spacers are painted or plated to prevent rust and improve visual appeal.

6

Quality Inspection

- Dimensional Inspection: Tools like calipers and micrometers are used to verify the dimensions of the spacers.

- Concentricity Inspection: The alignment of center and bolt holes is checked to ensure balance.

- Hardness Testing: The strength of the material is tested, particularly after heat treatment.

- Surface Quality Inspection: The surface finish is inspected for uniformity and defects.

7

Packaging and Shipping

- Assembly (if needed): Complex spacers with additional components like center rings are assembled.

- Cleaning: Any residual machining oils and impurities are removed from the spacers.

- Packaging: Spacers are packaged using protective materials to prevent damage during transit. Each package is labeled with product information and batch numbers for traceability.

- Shipping: The packaged spacers are stored in the warehouse and shipped to the client’s specified location, ready to enhance the performance and aesthetics of their vehicles.

By following these meticulous steps, we ensure that each custom wheel spacer meets the highest standards of quality and performance.

Contact FLEXIFORGED to Start Your Business

Have a look at how some of our clients perceive our goods and services: