Introduction: One Wheel, Many Possibilities — Which Structure Suits You Best?

Whether you’re a car builder, tuning shop, or aftermarket parts wholesaler, forged wheels are one of the most important performance upgrades your customers will demand. But when it comes to forged wheel structure, confusion is common.

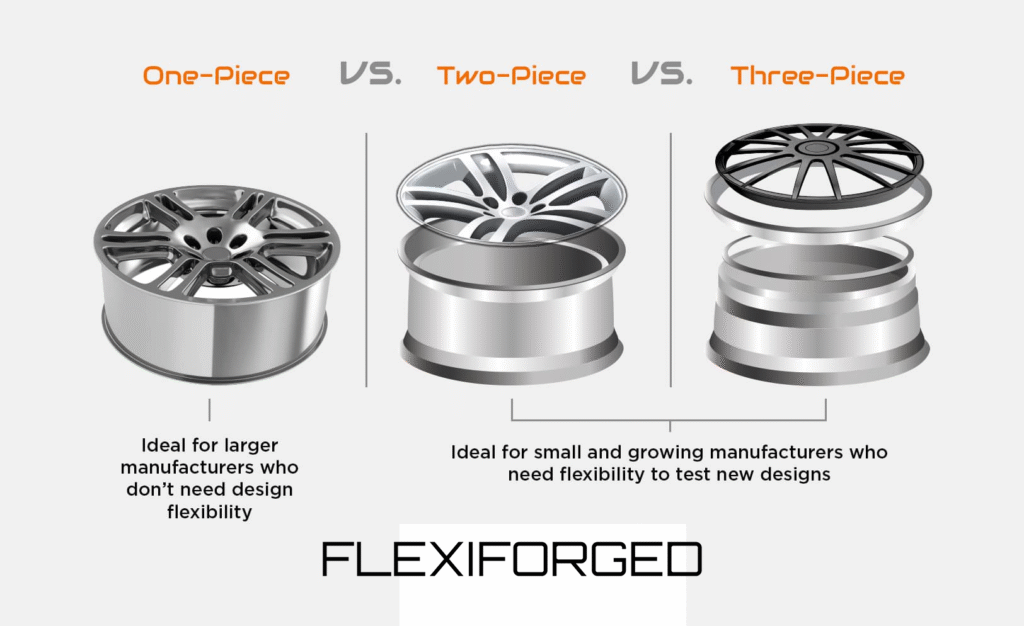

Should you choose monoblock, 2-piece, or 3-piece forged wheels? What’s the difference in weight, strength, customization, and maintenance? More importantly — what do your clients actually need?

This article gives you a clear, professional breakdown of each forged wheel design, compares them side-by-side, and answers real-world buyer questions. Whether you’re sourcing for daily drivers, track cars, off-road trucks, or luxury builds, this is your all-in-one guide.

Quick Overview: The 3 Main Types of Forged Wheels

| Type | Structure | Best For |

|---|---|---|

| Monoblock | Single solid forged piece | Max strength, minimal weight, track use |

| 2-Piece | Forged center + outer barrel | Custom width/offset, easier repairs |

| 3-Piece | Forged center + inner & outer barrels | Highest customization, modular repair |

1. Monoblock Forged Wheels – One Piece, One Purpose

🔧 Structure

- Milled from a single solid block of forged aluminum or magnesium

- No bolts, joints, or seams

✅ Advantages

- Strongest and lightest design due to seamless structure

- Zero leak risk — no sealing hardware

- Easiest to maintain — no bolts to check

- Sleek, clean visual appeal

❌ Disadvantages

- No flexibility to change width or offset once made

- If damaged, the entire wheel must be replaced

🚗 Ideal for:

- Track and race applications

- Daily drivers who want minimal maintenance

- Brands looking for clean, performance-focused designs

2. 2-Piece Forged Wheels – Balance of Strength & Customization

🔧 Structure

- Forged center + outer barrel (lip)

- Usually joined with bolts (removable) or welded (non-removable)

✅ Advantages

- Modular customization of width, offset, finish

- More cost-effective repair — outer barrel can be replaced

- Good balance of performance and flexibility

❌ Disadvantages

- Slightly heavier than monoblock due to joint hardware

- Requires bolt maintenance to avoid loosening over time

🚗 Ideal for:

- Tuning shops serving diverse customer preferences

- Street performance builds needing repair options

- Custom car builders seeking design variety

3. 3-Piece Forged Wheels – Maximum Flexibility, Premium Look

🔧 Structure

- Forged center + inner barrel + outer barrel

- All three parts joined with high-torque bolts

✅ Advantages

- Unlimited customization for width, offset, finish

- Parts can be replaced individually, reducing repair costs

- Easy to tune weight balance for performance optimization

❌ Disadvantages

- Heaviest structure (due to triple components & bolts)

- Highest maintenance — bolt rechecking and seal management

- More expensive due to complex production

🚗 Ideal for:

- Premium custom builds

- Motorsports teams needing fine-tuned performance

- Enthusiasts demanding unique looks and fitment

Side-by-Side Comparison Chart

| Feature | Monoblock | 2-Piece | 3-Piece |

|---|---|---|---|

| Structure | One solid piece | Center + outer barrel | Center + 2 barrels |

| Weight | Lightest | Moderate | Heaviest |

| Customization | Low | Medium | Maximum |

| Repairability | Low | Medium | High |

| Maintenance | Low | Medium | High |

| Cost | Low–Medium | Medium | High |

| Use Case | Track / OEM | Tuning / Street | Bespoke / Show / Track |

What Buyers Ask: Quick Answers to Real Questions

❓ What’s the difference between monoblock and 2-piece wheels?

Monoblock = one solid piece, lighter and stronger, but no flexibility.

2-piece = separate center and barrel, more repairable and customizable.

❓ What’s the difference between 2-piece and 3-piece wheels?

3-piece adds an inner barrel, allowing finer control over width and backspacing. Also offers more finish and color options.

❓ What does “forged monoblock” mean?

It means the wheel was milled from a single block of forged aluminum or magnesium, ensuring high strength and low weight.

❓ Are forged monoblock wheels good for daily driving?

Yes. They are durable, low-maintenance, and resistant to fatigue — making them perfect for both street and performance use.

❓ Can forged wheels crack or bend?

Yes, but less likely than cast wheels. Forged wheels have higher tensile strength and better fatigue resistance.

❓ How to tell if a wheel is 2-piece or 3-piece?

Look for visible bolts and seams:

- 2-piece: seam between center and outer barrel

- 3-piece: seams between center, inner barrel, and outer lip

❓ What is the best forged wheel brand?

There are many reputable names:

- FLEXIFORGED (China) – B2B factory-direct supplier for custom forged monoblock, 2-piece, and 3-piece wheels

- HRE, BBS, Forgeline, Vossen, Brixton Forged, Rotiform – high-end U.S./EU aftermarket brands

- Choose based on project needs, pricing, and supplier responsiveness

❓ Are forged wheels worth the investment?

If your customers care about performance, style, and strength — absolutely. Forged wheels reduce weight, improve handling, and offer long-term durability.

❓ What type of wheels are the strongest?

Forged monoblock wheels are the strongest by design. But high-quality 3-piece wheels can also be engineered to meet race-spec load requirements.

❓ What to avoid when buying forged rims?

- Lack of ISO9001 / IATF16949 certification

- No clear communication or export experience

- Missing invoice info (e.g., HS code, declared value)

- No QC reports, poor packaging, or fake material claims

Choosing the Right Structure for Your Business or Clients

| If your priority is… | Choose… |

|---|---|

| Maximum strength and light weight | Monoblock |

| Moderate customization and repairability | 2-Piece |

| Highest flexibility and premium styling | 3-Piece |

For most B2B tuning shops, a combination of 6061-T6 monoblock wheels and modular 2-piece wheels meets 80% of customer needs. High-end or niche builds may call for 3-piece structures.

FLEXIFORGED — Your B2B Partner for Forged Wheel Structures

At FLEXIFORGED, we manufacture monoblock, 2-piece, and 3-piece forged wheels in small batches — tailored for your market.

- ✅ Over 60 CNC machines, including 5-axis centers

- ✅ ISO9001 and IATF16949 certified

- ✅ Export experience to Europe, North America, South Africa

- ✅ Support for custom engraving, private labels, logo machining

- ✅ Forged lips, barrels, and wheel parts also available

📧 jackie.wei@flexiforged.com

🌐 www.flexiforgewheel.com

Tell us your size, material, and structure preferences — we’ll build it.