Technical Documentation

Engineering knowledge and standards for custom forged wheels.

Welcome to FLEXIFORGED Technical Documentation Center

FLEXIFORGED provides complete engineering resources for our global partners — from OEM manufacturers to tuning shops.

This documentation summarizes everything you need to understand our forging process, materials, fitment standards, and testing procedures.

Whether you’re a technical buyer or simply exploring forged wheels, this page gives you a clear, trustworthy overview — no deep research required.

You’ll also find download options and contact links for detailed data and CAD support.

Explore Our Technical Topics

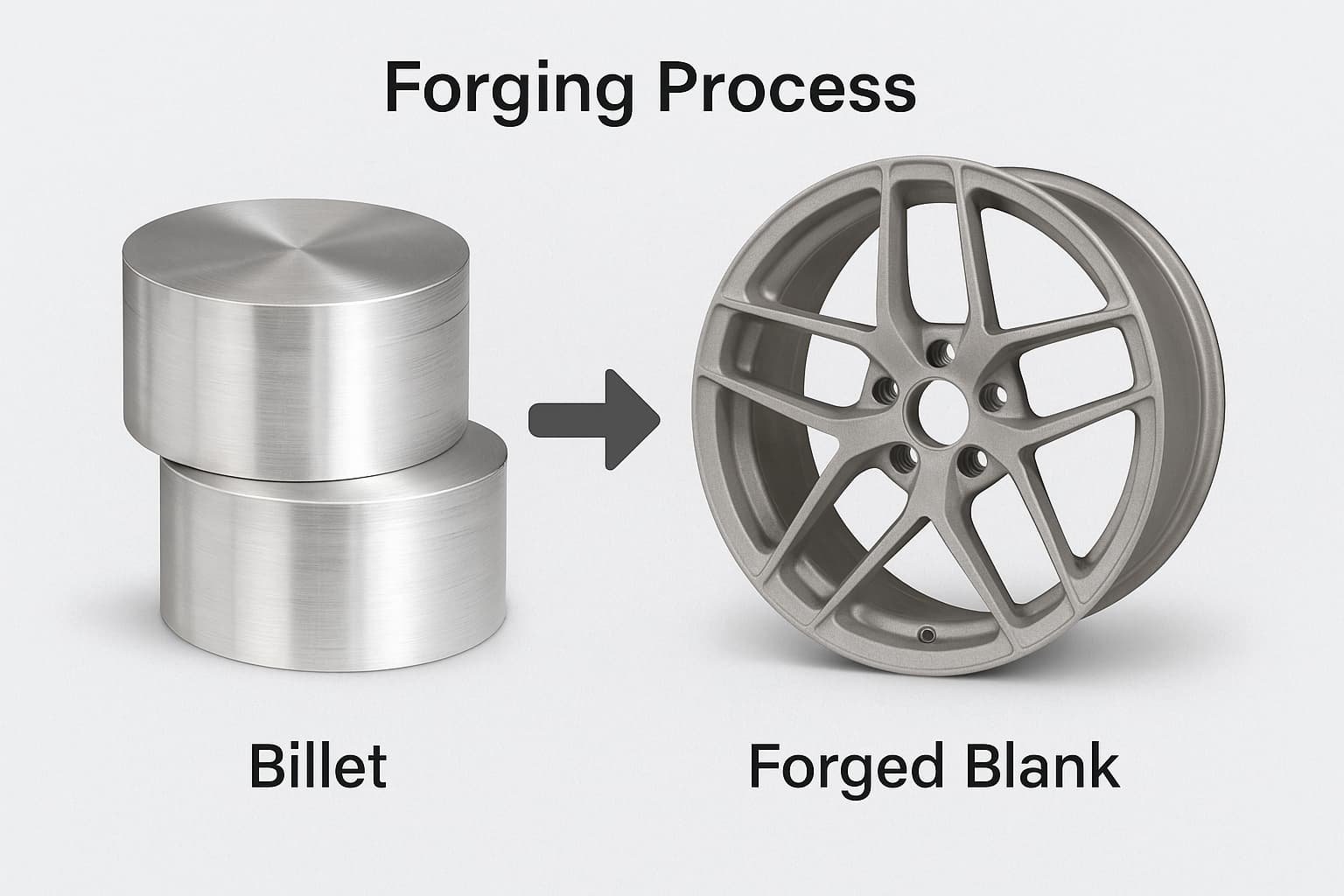

1️⃣ Forging Process Explained

Learn how solid aluminum and magnesium billets are transformed into high-strength forged wheels.

The process involves multi-ton forging pressure, T6 heat treatment, and 5-axis CNC machining, resulting in exceptional structural density and precision fitment.

Unlike casting, forging realigns the metal grain, dramatically increasing toughness and reducing weight.

That’s why every FLEXIFORGED wheel offers both strength and agility.

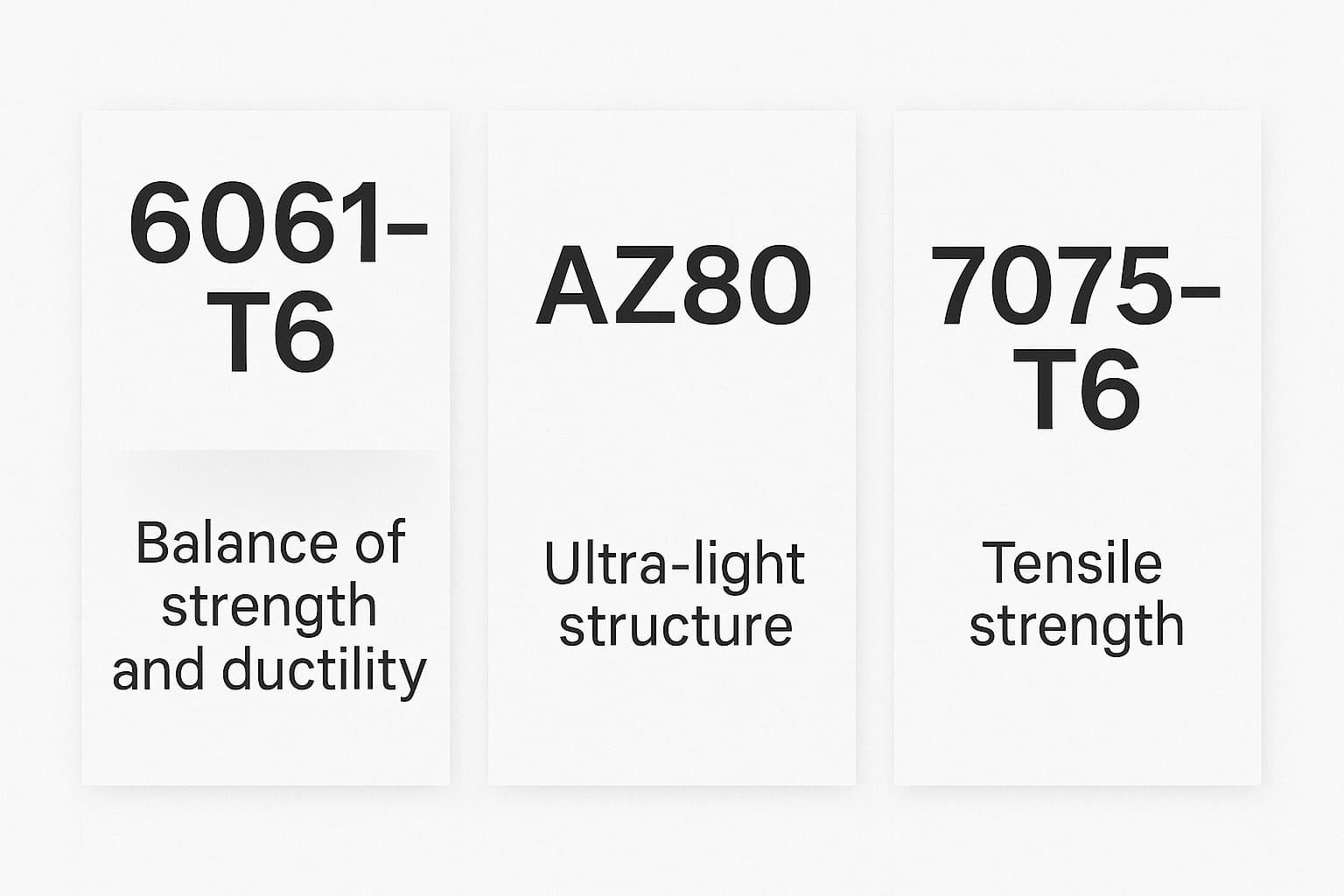

2️⃣ Material Standards & Properties

FLEXIFORGED primarily uses 6061-T6 forged aluminum and AZ80 magnesium alloy.

6061-T6 offers the ideal balance of strength, ductility and corrosion resistance for daily and performance use.

AZ80 magnesium provides an ultra-light structure, reducing unsprung mass by up to 25% — perfect for racing or EV applications.

We also offer 7075-T6 for special motorcycle wheel projects where maximum tensile strength is required, though it’s less common in wheel production.

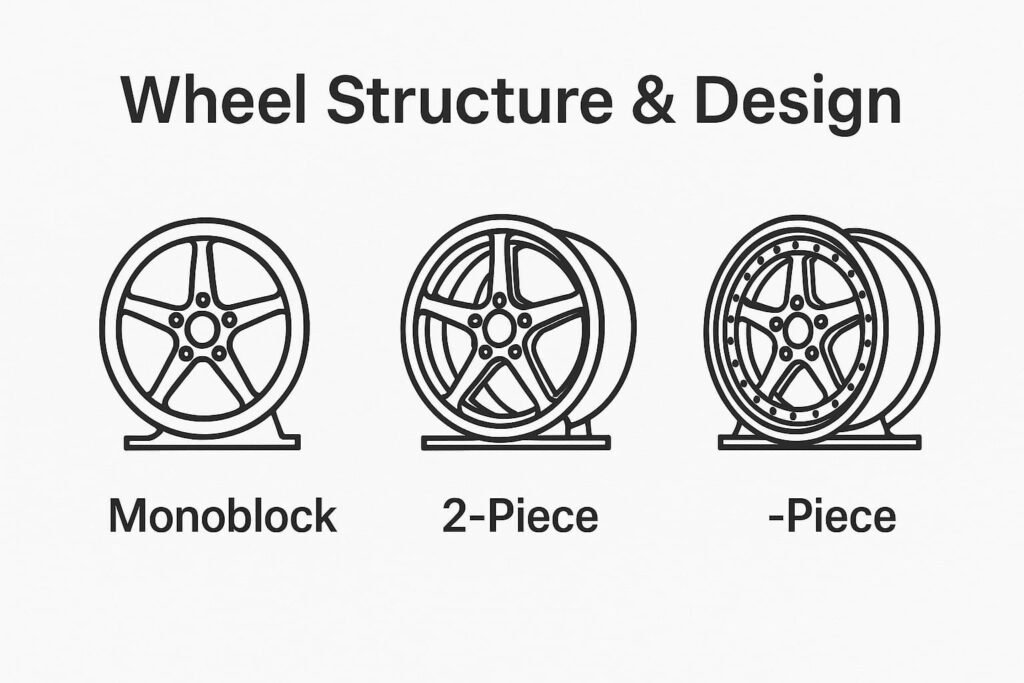

3️⃣ Wheel Structure & Design

Forged wheels come in multiple configurations: Monoblock, 2-piece, and 3-piece.

Each structure serves different goals — Monoblock for precision and strength, 2-piece for flexibility and offset tuning, 3-piece for aesthetic customization.

FLEXIFORGED designs every wheel with a balance between aerodynamics, brake clearance, and visual harmony.

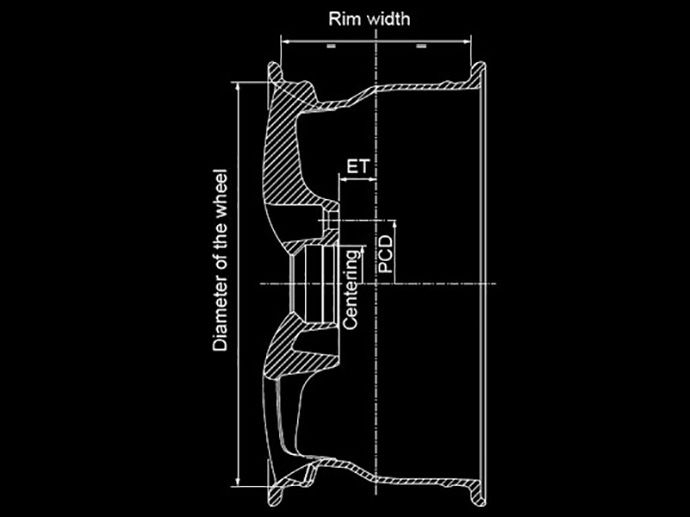

4️⃣ Fitment Terminology Guide

Wheel fitment is all about perfect geometry: PCD, offset (ET), width, and center bore.

Misunderstanding these values can cause vibration or brake interference.

This guide helps you easily interpret measurements and ensure exact compatibility for any vehicle platform.

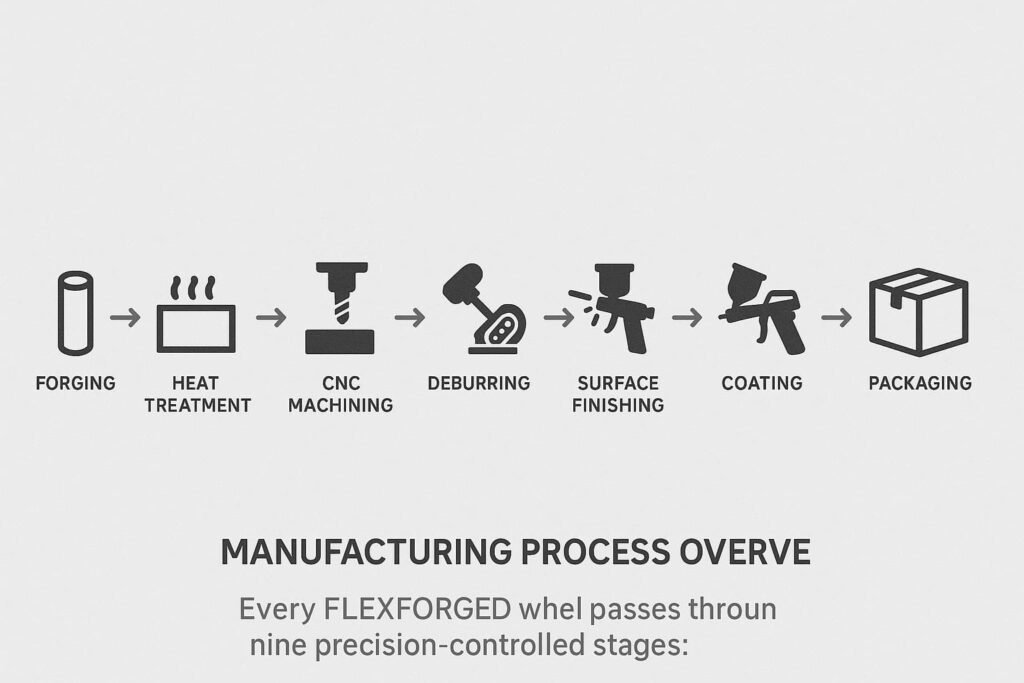

5️⃣ Manufacturing Process Overview

Every FLEXIFORGED wheel passes through nine precision-controlled stages:

forging → heat treatment → CNC machining → drilling → deburring → surface finishing → coating → quality inspection → packaging.

From billet to final wheel, we track and record every process to guarantee consistency and compliance with ISO 9001 standards.

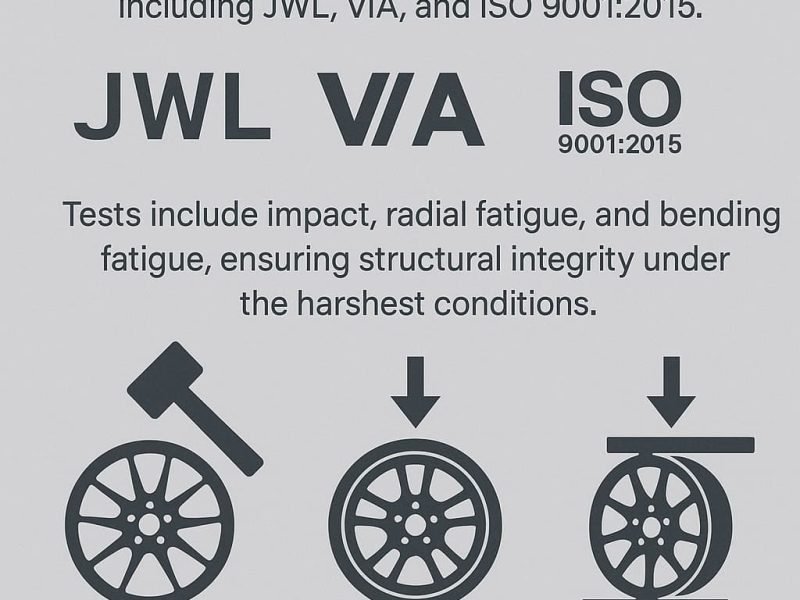

6️⃣ Testing & Certification Standards

Our wheels are tested to international standards including JWL, VIA, and ISO 9001:2015.

Tests include impact, radial fatigue, and bending fatigue, ensuring structural integrity under the harshest conditions.

7️⃣ Installation & Torque Guide

Proper installation ensures long-term performance and safety.

Use a torque wrench, tighten in a star pattern, and re-check torque after 100 km of driving.

View our torque chart and installation tips to prevent over-tightening or hub stress.

8️⃣ Maintenance & Refinishing

Forged wheels are easy to maintain when properly cared for.

Clean using pH-neutral cleaners, avoid acidic solutions, and wax polished surfaces to maintain shine.

Learn how to safely refinish or repair damaged wheels without compromising structure.

9️⃣ Downloadable Specs & Catalog

Want technical sheets, brake clearance data, or custom CAD drawings?

Contact our engineering team — we’ll provide the right files based on your vehicle or project.

FLEXIFORGED keeps an extensive database of fitment and caliper data for OEMs and tuning specialists.

Core Technical Data Summary

Material Comparison Table

| Material | Density (g/cm³) | Tensile Strength (MPa) | Features / Application |

|---|---|---|---|

| 6061-T6 Aluminum | 2.70 | 310 | Excellent balance of strength, corrosion resistance, and machinability. Ideal for performance and daily forged wheels. |

| AZ80 Magnesium Alloy | 1.80 | 280 | 35% lighter than aluminum, superior vibration damping, ideal for racing and EV projects. |

| 7075-T6 Aluminum | 2.81 | 480 | High tensile strength, used in aerospace or special high-load projects. |

📎 Note: FLEXIFORGED performs material verification and heat treatment in-house to ensure consistent 6061-T6 and AZ80 mechanical performance.

Recommended Torque Values

| Bolt Size | Torque (Nm) | Vehicle Type |

|---|---|---|

| M12×1.25 | 110 | Compact & passenger cars |

| M12×1.5 | 115 | Mid-size sedans |

| M14×1.5 | 130 | SUVs / performance cars |

| M14×2.0 | 150 | Trucks / off-road vehicles |

💡 Always re-torque wheels after 100 km of driving.

Need Full Engineering Data or OEM Support?

FLEXIFORGED engineers provide technical drawings, fitment validation, and OEM customization.

Submit your request — our team will reply with the correct data within 24 hours.