For off‑road drivers, motorsport enthusiasts, and high‑performance builders, wheel choice isn’t just about aesthetics — it’s about functionality, safety, and performance. One of the topics that often comes up in wheel sourcing discussions is the concept of beadlock wheels and how they differ from standard forged wheels.

This article explains what beadlock wheels are, why they’re used, the key differences compared to normal forged wheels, and how to choose the right solution based on your application. Whether you’re a procurement leader, a tuning shop owner, or an OEM custom‑wheel specifier, this guide will help you make informed decisions.

What Is a Beadlock Wheel?

A beadlock wheel is a type of wheel that includes a mechanical ring or clamp that physically secures the tire’s bead — the edge of the tire — to the wheel rim. In a standard wheel setup, the tire bead is held against the rim by air pressure alone. If pressure drops too low, the bead can “de‑seat” or slip, especially under heavy load or extreme cornering forces. Beadlock wheels solve this by bolting the tire bead directly to the rim so it stays in place even at very low air pressures. Mount Zion Offroad+1

This design is especially important in extreme off‑road conditions or competitive environments where drivers want maximum traction, often achieved by running very low tire pressures. Standard wheels simply cannot reliably hold the bead at extremely low PSI without risk of separation. MotorTrend

Components of a Beadlock Wheel

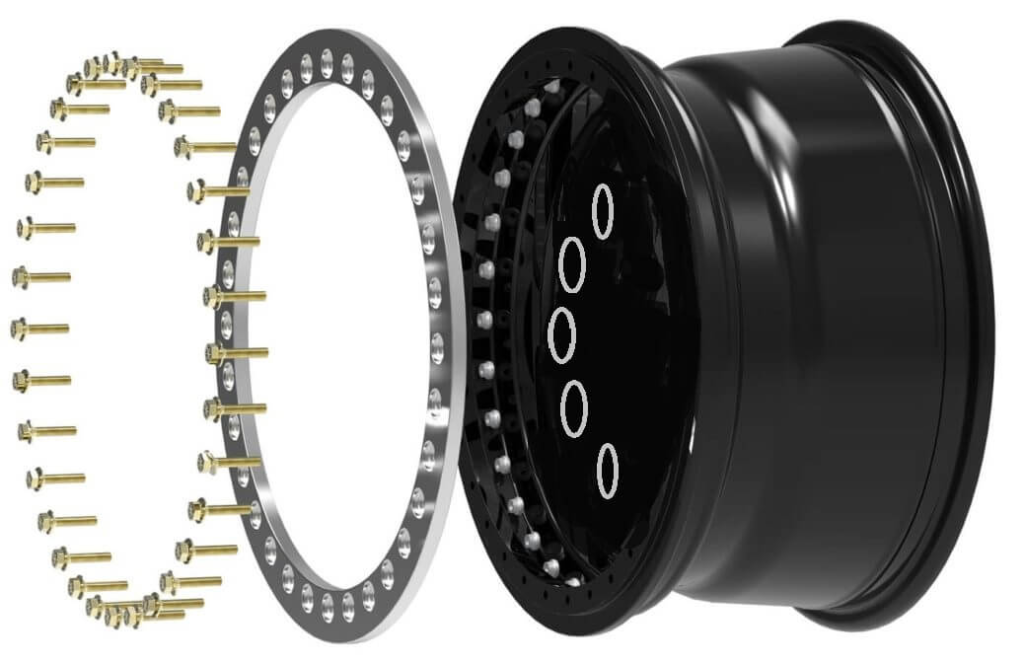

A typical mechanical beadlock wheel consists of:

- Outer Beadlock Ring: A heavy‑duty metal ring that bolts onto the wheel’s outer lip

- Bolts and Fasteners: Evenly spaced around the circumference to clamp the bead

- Wheel Rim Body: The core structure, which may be cast, forged, or billet machined

When installed, the tire’s bead is sandwiched between the wheel and the beadlock ring, ensuring a solid mechanical hold that doesn’t rely on tire pressure. litespeedracing

Standard Forged Wheels: How They Work

Standard forged wheels — whether for street, track, or light off‑road use — are typically manufactured from a solid billet through a high‑pressure forging process. This produces a wheel with high strength‑to‑weight characteristics. BBS USA

However, forged wheels do not include a beadlock mechanism. They rely entirely on normal tire pressure to keep the bead seated securely on the rim. For most road and moderate off‑road uses, this is sufficient and offers benefits such as lower weight, improved handling, and reduced rotational mass. Wikipedia

Key Differences Between Beadlock and Standard Forged Wheels

Here’s a direct comparison of what sets beadlock wheels apart from standard forged wheels:

1. Tire Bead Security

- Beadlock wheels: Mechanically clamp the tire bead to the rim, allowing safe operation at very low air pressures without de‑beading risk. Mount Zion Offroad

- Standard forged wheels: Depend on air pressure to keep the bead seated, which limits how low you can safely run tire pressures. Wikipedia

2. Performance Use Cases

- Beadlock wheels: Designed for extreme off‑road, rock crawling, or drag racing where traction at low pressures or high torque forces are needed. litespeedracing

- Standard forged wheels: Best for street, track, or light off‑road applications where tire pressure remains within normal limits. Wikipedia

3. Maintenance and Complexity

- Beadlock wheels: Require periodic maintenance, including checking and torquing of bolts to prevent leaks or loosening. MotorTrend

- Standard forged wheels: Generally maintenance‑free with no additional hardware to service beyond regular tire balancing and rotation. Wikipedia

4. Weight and Efficiency

- Beadlock wheels: Typically heavier due to the locking ring and hardware, which may affect fuel economy or unsprung mass. MotorTrend

- Standard forged wheels: Lighter overall, contributing to better on‑road performance and efficiency. Wikipedia

5. Street Legality

- Beadlock wheels: Many beadlock wheels are labeled “Off‑Road Use Only” and may not meet street legality or insurance compliance. MotorTrend

- Standard forged wheels: Fully street‑legal with normal DOT compliance for everyday driving. Wikipedia

6. Appearance vs Function

- Simulated (faux) beadlocks: Some wheels include beadlock‑style bolts purely for aesthetic effect. These look rugged but do not function as beadlocks and perform like standard wheels. AST Forged Wheels

- True beadlock wheels: Provide genuine mechanical bead retention. litespeedracing

When Should You Choose a Beadlock Wheel?

Beadlocks are best suited for vehicles and builds where tire bead separation at low pressure is a real concern — such as:

- Rock crawling or technical off‑road trails

- Desert racing, sand dune exploration

- Drag racing with high torque builds

- Vehicles that routinely operate at very low tire pressures

If your use case is everyday driving, street performance, or mild off‑road, a high‑quality standard forged wheel is usually the more practical and compliant choice.

Beadlock Wheels vs. Standard Forged Wheels: Cost & Value

Beadlock wheels — especially true mechanical beadlocks — tend to cost more and require careful setup and maintenance. Standard forged wheels may cost less while offering benefits in performance, weight savings, and compliance.

In some markets, faux beadlock wheels — often forged but decorative — strike a balance: they provide a rugged look without true bead retention but are more cost‑effective and easier to service. AST Forged Wheels

Safety and Legal Considerations

Before opting for beadlock wheels, you should:

- Verify street legality and insurance compliance in your region

- Ensure wheels are installed by experienced tire professionals

- Plan for routine inspection of beadlock hardware

Because beadlock bolts and rings can loosen over time, ongoing maintenance is key if these wheels are used regularly. MotorTrend

Conclusion — Choosing the Right Wheel for Your Needs

Beadlock wheels serve a specialized purpose for vehicles in extreme environments where tire bead security at low pressure is essential. Standard forged wheels, on the other hand, offer excellent strength‑to‑weight ratios, everyday usability, and broader compliance for street and performance uses.

Understanding the differences — and the practical implications of each — helps you align wheel choice with your customers’ needs, whether it’s a high‑performance off‑road rig or a premium street build.

If you’d like assistance evaluating beadlock options or selecting forged wheel solutions tailored to your build specifications, our team can help compare performance, compliance, and long‑term value.